Cost-efficient Ceramic Coating Philadelphia Solutions for Lavish Finishes

Cost-efficient Ceramic Coating Philadelphia Solutions for Lavish Finishes

Blog Article

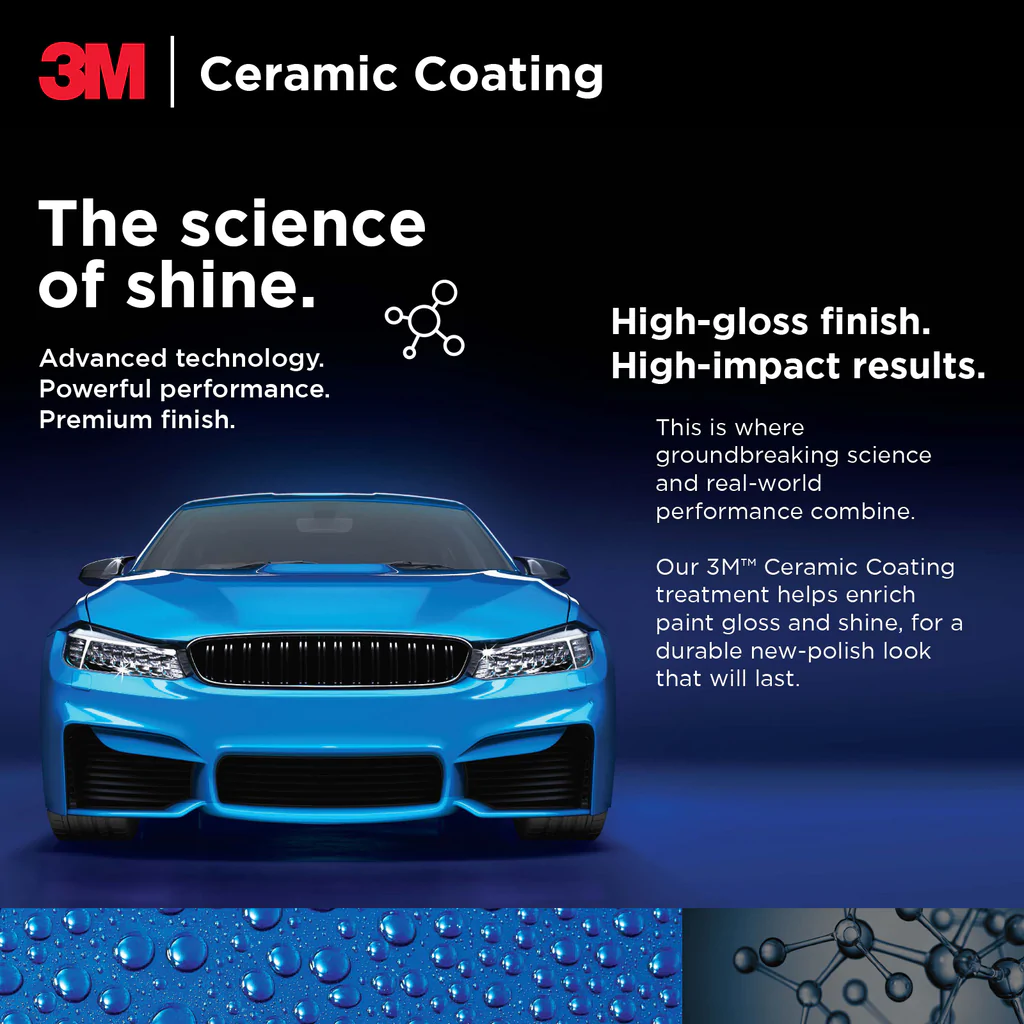

Why Ceramic Covering Is the Ultimate Option for a Remarkable Complete

Ceramic finish has actually become a leading option for those looking for a perfect finish for their cars, thanks to its remarkable resilience and safety features. This innovative fluid polymer not only bonds effortlessly with factory paint yet likewise uses an awesome barrier versus usual risks such as scrapes, UV rays, and toxic wastes. Its hydrophobic residential or commercial properties simplify maintenance while boosting aesthetic appeal. Comprehending just how this innovation contrasts to standard techniques and discovering its application subtleties can disclose also more about its worth. What aspects really set ceramic coating apart?

What Is Ceramic Covering?

When applied appropriately, ceramic coating produces a hydrophobic surface area that drives away water and dirt, making it less complicated to keep and clean. Unlike traditional waxes or sealers, which typically supply short-lived security, ceramic coatings can last for a number of years, depending upon the item top quality and application approach. The procedure of using ceramic covering calls for thorough preparation, including detailed cleaning and sometimes repaint adjustment, to make certain optimum bonding and performance.

Ceramic layers are not limited to automobile surface areas; they can likewise be used on numerous materials, consisting of glass, steel, and plastics, providing a functional remedy for enhancing security. In general, ceramic finish stands for a significant innovation in surface security innovation, integrating both useful and visual benefits for a variety of applications.

Benefits of Ceramic Layer

While numerous surface area defense options exist, the advantages of ceramic finishing stand out due to its distinct buildings and durable efficiency. Among the key advantages is its remarkable toughness. Ceramic Coating Philadelphia. Unlike typical wax or sealants that require frequent reapplication, ceramic finishes provide a durable layer that can last for a number of years, considerably minimizing upkeep initiatives

An additional significant benefit is improved protection versus ecological contaminants. Ceramic finishes develop a hydrophobic surface area that drives away water, dust, and numerous toxins, making it less complicated to cleanse. This attribute not only protects the automobile's look however also reduces the threat of deterioration and oxidation, especially in rough weather.

Additionally, ceramic coverings offer remarkable resistance to UV rays, preventing fading and degradation of paint in time. This UV security is critical for preserving the aesthetic worth of lorries and surfaces exposed to route sunshine.

Additionally, the shiny surface accomplished with ceramic coating enhances the total aesthetic allure, giving surface areas a showroom-quality luster. Overall, ceramic coatings stand for a significant development in surface security innovation, providing enduring advantages that deal with both practical and aesthetic requirements.

Just How It Works

Understanding the science behind ceramic coverings discloses exactly how they provide such exceptional defense and durability. At its core, a ceramic coating is a liquid polymer that chemically bonds with the vehicle's manufacturing facility paint. This bonding creates a safety layer that is both hydrophobic and oleophobic, repelling water, dirt, and oil. The primary part of many ceramic coatings is silicon dioxide (SiO2), which is originated from quartz. This compound adds to the coating's solidity and resistance to scratches, UV rays, and ecological impurities.

The application process involves several actions, consisting of surface area prep work, which is essential to accomplishing optimum adhesion. When used, the layer undergoes a healing process, during which it solidifies and creates a semi-permanent bond with the paint surface. This bond is what identifies ceramic finishings from traditional waxes and sealers, offering a longer-lasting safety barrier that can withstand for years.

Additionally, the thickness of the coating can boost its safety top qualities, making certain that it can hold up against harsh problems. Eventually, the science of ceramic coverings integrates sophisticated materials with cutting-edge application methods to provide an unequaled level of protection and aesthetic improvement for cars.

Contrast With Standard Techniques

The benefits of ceramic finishings end up being particularly apparent when compared to traditional paint protection techniques such as sealers and waxes. While waxes use a short-lived sparkle, generally lasting a couple of weeks to a pair of months, ceramic coverings provide a long-lasting safety layer that can withstand for several years. This toughness dramatically reduces the frequency of reapplication, making ceramic coatings an extra cost-efficient service in time.

Furthermore, typical approaches commonly call for substantial preparation and several applications to attain click here to read a sufficient level of defense. On the other hand, ceramic coverings bond at a molecular level with the vehicle's surface area, producing a robust shield against ecological impurities like UV rays, acid rainfall, and road salts. This bond improves the car's resistance to scratches and swirl marks, which are widespread with conventional waxes and sealants.

Additionally, the hydrophobic homes of ceramic coatings fend off water and dirt, resulting in simpler cleaning and upkeep. On the other hand, wax and sealant-treated surfaces can draw in gunk, demanding even more frequent cleaning - Ceramic Coating Philadelphia. On the whole, ceramic finishes not just supply superior protection but likewise supply a more enduring and aesthetically enticing surface, developing them as the favored choice for discerning lorry proprietors

Application and Upkeep Tips

Using a foam applicator, apply the coating in small sections, adhering to the producer's guidelines pertaining to density and overlap. Permit sufficient treating time between layers, commonly 24 hours, to make sure appropriate bonding. After application, it is essential to prevent direct exposure to water or harsh elements for a minimum of a week to enable the finishing to totally heal.

For maintenance, wash the automobile on a regular basis with pH-balanced soaps and stay clear of unpleasant materials. Touchless car cleans are recommended to decrease damaging. In addition, utilizing a ceramic maintenance spray can boost the finish's hydrophobic homes and longevity. Routine assessments for any go to website signs of wear will certainly assist keep the covering's honesty and protect that excellent coating.

Verdict

To conclude, ceramic finish becomes a remarkable alternative for accomplishing a flawless auto finish. Its phenomenal toughness, safety qualities, and hydrophobic residential or commercial properties substantially boost the vehicle's appearance while simplifying upkeep efforts. By forming a robust bond with factory paint, ceramic covering properly guards versus scratches, UV rays, and environmental pollutants. With a life-span expanding several years, this innovative option not only preserves yet also elevates the total visual charm of vehicles, making it a cost-efficient financial investment for auto fanatics.

Report this page